The Role of CAD Software in Our Product Design

Introduction:

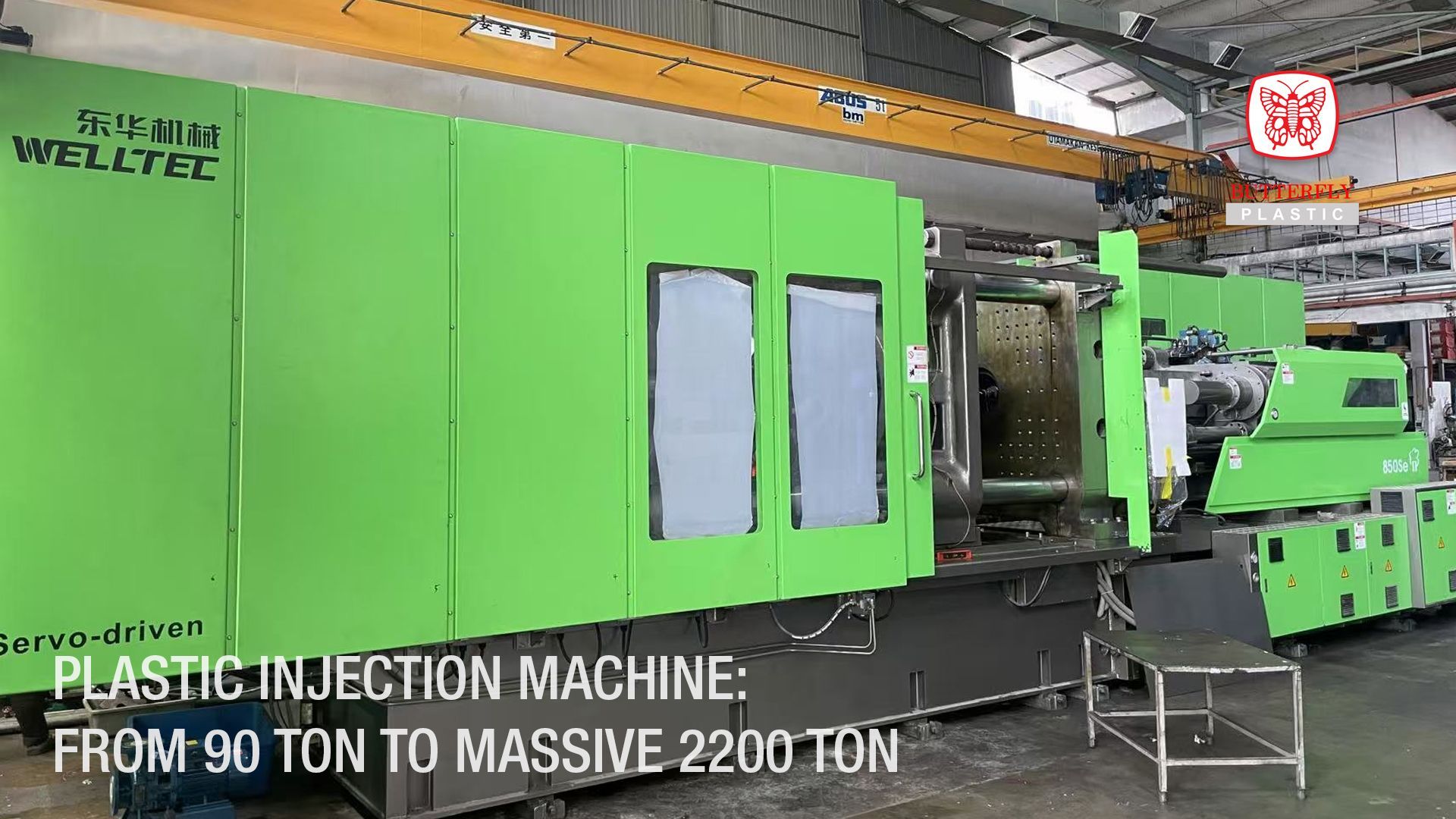

At our esteemed plastic injection manufacturing company, we go beyond traditional design approaches to provide our valued clients with tailored solutions that meet their specific application requirements. With our expertise in CAD software and advanced simulation capabilities, we have the ability to custom design and rigorously test products to ensure optimal performance and reliability. In this article, we will explore how our integrated approach to custom design and simulation empowers us to deliver exceptional results for our clients.

Understanding Your Application Needs:

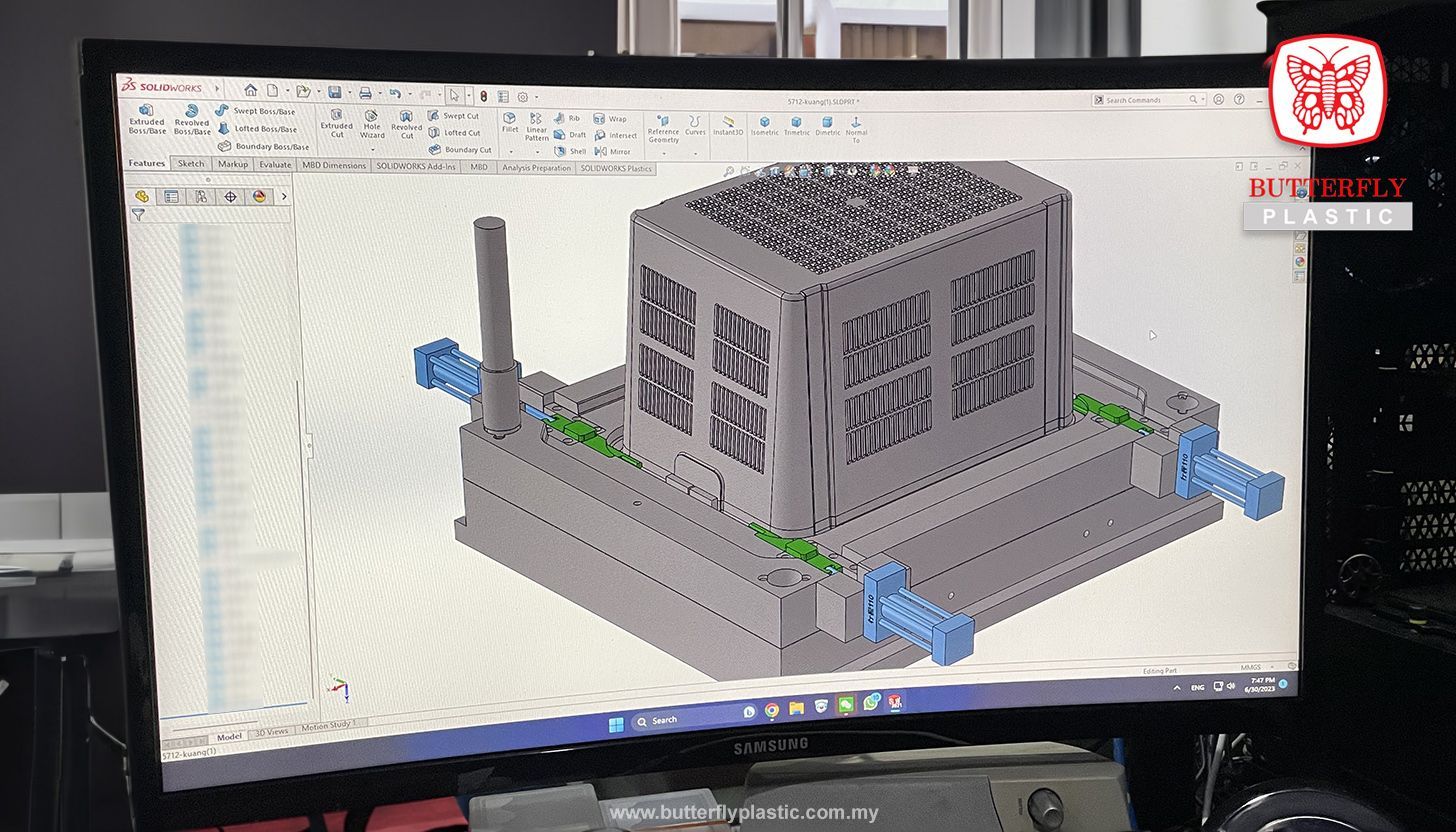

We recognize that understanding your unique application requirements is crucial to designing a product that meets your expectations. Our team takes the time to thoroughly understand the challenges and demands of your application, enabling us to develop a comprehensive design strategy. By leveraging CAD software, we create detailed 3D models that accurately represent your envisioned product. This collaborative process ensures that the custom-designed solution is tailored precisely to fit your application.

Unleashing Design Creativity:

CAD software serves as a powerful tool for unleashing our design creativity and innovation. With its versatile features, we can explore various design possibilities and solutions that address your specific needs. From complex geometries to intricate assemblies, CAD allows us to visualize and refine the design iteratively. This iterative process not only ensures that the final design meets your expectations but also allows for adjustments and enhancements based on your feedback. CAD software enables us to create visually appealing and functional designs that seamlessly integrate with your application.

Simulation for Optimal Performance:

Our commitment to delivering excellence goes beyond the design phase. With advanced simulation capabilities, we subject our custom-designed products to rigorous testing to ensure optimal performance and reliability. Load tests enable us to assess how the product withstands various stress factors, ensuring that it can handle the expected operating conditions. Drop tests allow us to evaluate the product's durability and ability to withstand impacts. By simulating real-world scenarios, we can identify and address potential issues before the manufacturing process begins, resulting in a superior end product.

Enhancing Reliability and Safety:

Simulation plays a vital role in enhancing the reliability and safety of our custom-designed products. By subjecting the design to virtual tests, we can identify potential weaknesses, areas of stress concentration, and points of failure. This knowledge allows us to optimize the design, strengthening critical areas and improving overall durability. Through simulation, we ensure that the product meets industry standards and regulatory requirements, providing you with a solution that is not only innovative but also safe and reliable.

Collaboration and Iteration:

Our integrated approach to custom design and simulation fosters effective collaboration and iteration. By involving you in the simulation process, we can gather valuable insights and feedback. This collaborative feedback loop enables us to refine the design iteratively, ensuring that the final product meets your expectations. Our goal is to deliver a solution that not only fits your application but also provides a seamless user experience and maximum value.

Conclusion:

With our combined expertise in custom design and simulation, we offer tailored solutions that go above and beyond your expectations. Through the power of CAD software and advanced simulation capabilities, we transform your vision into a reality, providing a custom-designed product that fits your application perfectly. By incorporating load testing, drop testing, and other simulations, we ensure optimal performance, reliability, and safety. When you choose us as your partner, you gain access to our comprehensive approach, where design creativity, rigorous testing, and collaborative iteration converge to deliver exceptional results.

WHERE TO FIND US

Plot 22, Lot P.T. 51680, Kawasan Perindustrian Taman Meru, Jelapang, 30020 Ipoh, Perak, Malaysia.

PRODUCTS

All Rights Reserved | Teo Mah Poh Plastic Industry Sdn Bhd